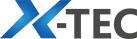

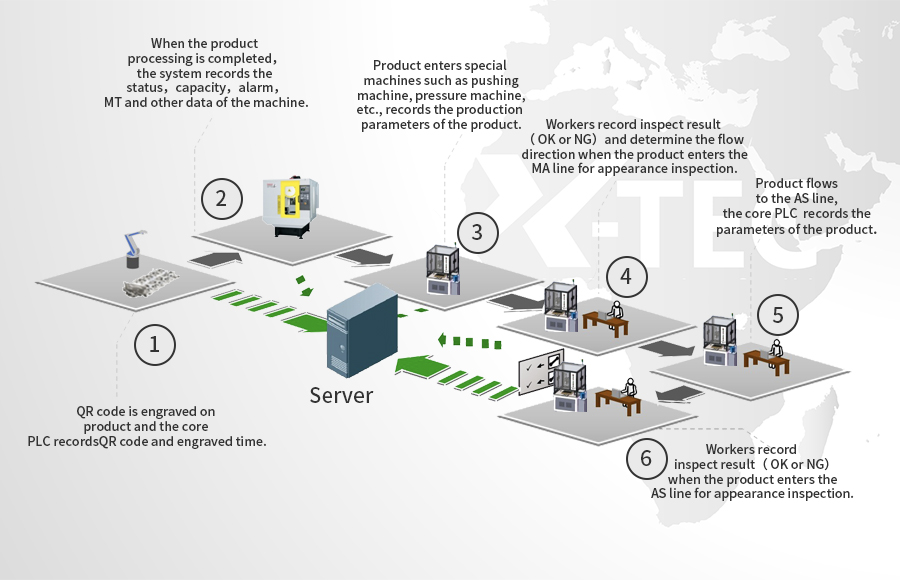

Common trace way ※Manual paper recording, waste of manpower and low efficiency; ※Process flow is strenuous, easy to make mistakes; ※Cost a lot of manpower and time to trace quality problems, resulting in the failure of quick response and low efficiency after the occurrence of abnormalities; ※The low efficiency of quality control causes great loss to the brand construction and after-sale cost of the enterprise. XMES trace way ※Use QR code and other technologies to improve the accuracy; ※Save the time of product file preservation and archiving, and reduce mis-operation; ※Ensure the penetration of quality traceability data and the completeness and accuracy of quality data information; ※Achieve quality control, standardized production management, and standardization. Provide accurate traceability platform support for quality anomaly improvement. |